Design and production of scientific instruments for synchrotron light sources,

nuclear physics research and analytical laboratories

ABOUT US

CINEL was founded in Padua in the 70’s with a technical partnership of INFN LNL Legnaro Laboratory on particle accelerator projects and since then has been involved in some of the most challenging projects all over Europe.

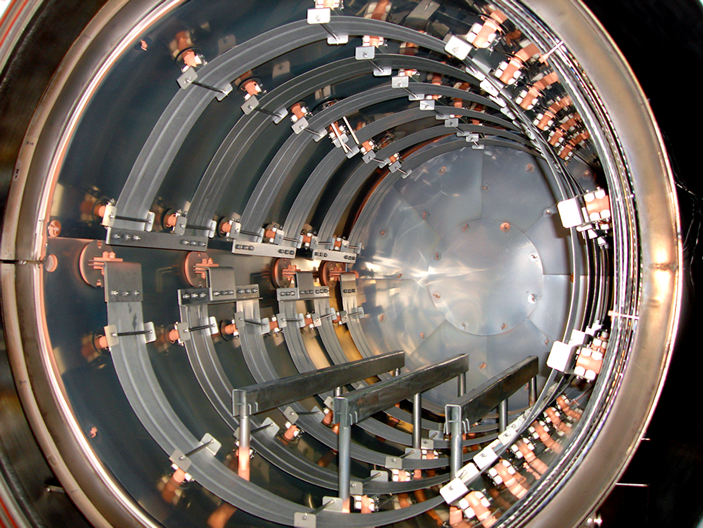

Nowadays, CINEL has reached a long experience on mechanical design and manufacture of apparatuses in several scientific and research fields such as Synchrotron Light Sources (monochromators, fully integrated front ends and beam lines, experimental chambers), as well as accelerator components (vacuum chambers, accelerating cavities, radiofrequency quadrupole cavities).

CINEL has acquired skilled experience in the field of cryogenics, superconductivity , astrophysics and bio-mechanics collaborating with well-known institutions as a qualified partner in the mechanical, thermal and control system design and it can now propose turnkey solutions with high level standardization.

CAD-CAM environment and CNC machines allow Cinel to fully develop whole technical projects, from the design phase to the product certification taking care of all the electro-mechanical, pneumatic and hydraulic aspects.

OUR SERVICES

DESIGN AND ENGINEERING

CINEL staff includes a team of engineers (3 mechanical engineers, 1 electromechanical engineer, 2 physicists) with significant experience and skill on all the engineering aspects of the beamline/synchrontron and RF components design.

MACHINING

Our internal workshop in equipped with machining centers such as milling machines (with working strokes up to x=4000mmmm, y=1200mm z=2000mm), turning milling machine (turn with auxiliary motorized spindle, up to diameter of 800mm and length 3000mm) and two EDW machines.

ASSEMBLY AND TESTING

The company personnel is properly trained to work according the requirements for manufacturing, handling and assembly UHV components. 10 people are daily involved in assembly and testing UHV components.

INSTALLATION AND COMMISSIONING

Upon request CINEL provides the installation and technical support for the commissioning of the equipment such as beam lines, monochromators, mirror chambers and front ends.

VACUUM BRAZING

CINEL has acquired during the last years a relevant experience in the vacuum brazing and thermal treatment activity on a wide range of materials such as stainless steel, copper, Glidcop, and ceramics.

WELDING

CINEL is equipped with MIG and TIG welding equipment: TIG Miller and Genesis type, MIG type Castomig and welding positioner.

Different metals and alloys can be welded in house.

OUR EQUIPMENT

Brazing vacuum furnace: an horizontal vacuum furnace for high temperature and high vacuum heat treatment and process is installed in our premises…

- Machining equipments: our internal workshop in equipped with a series of new generation machining centers, milling machines…

Clean room tent: we have installed a laminar flow clean tent unit (each laminar flow module achieves the criteria of clean room class 100 according…)

- Metrology equipments: an additional air conditioned room is available only for special dimensional tests…

- Welding and cleaning equipments: the welding equipment integrates the workshop area. CINEL is equipped with MIG and TIG welding equipment…

- UHV vacuum test benches: three fully equipped test benches are available for bake-out procedure